MARLON GARCIA

HP

Description

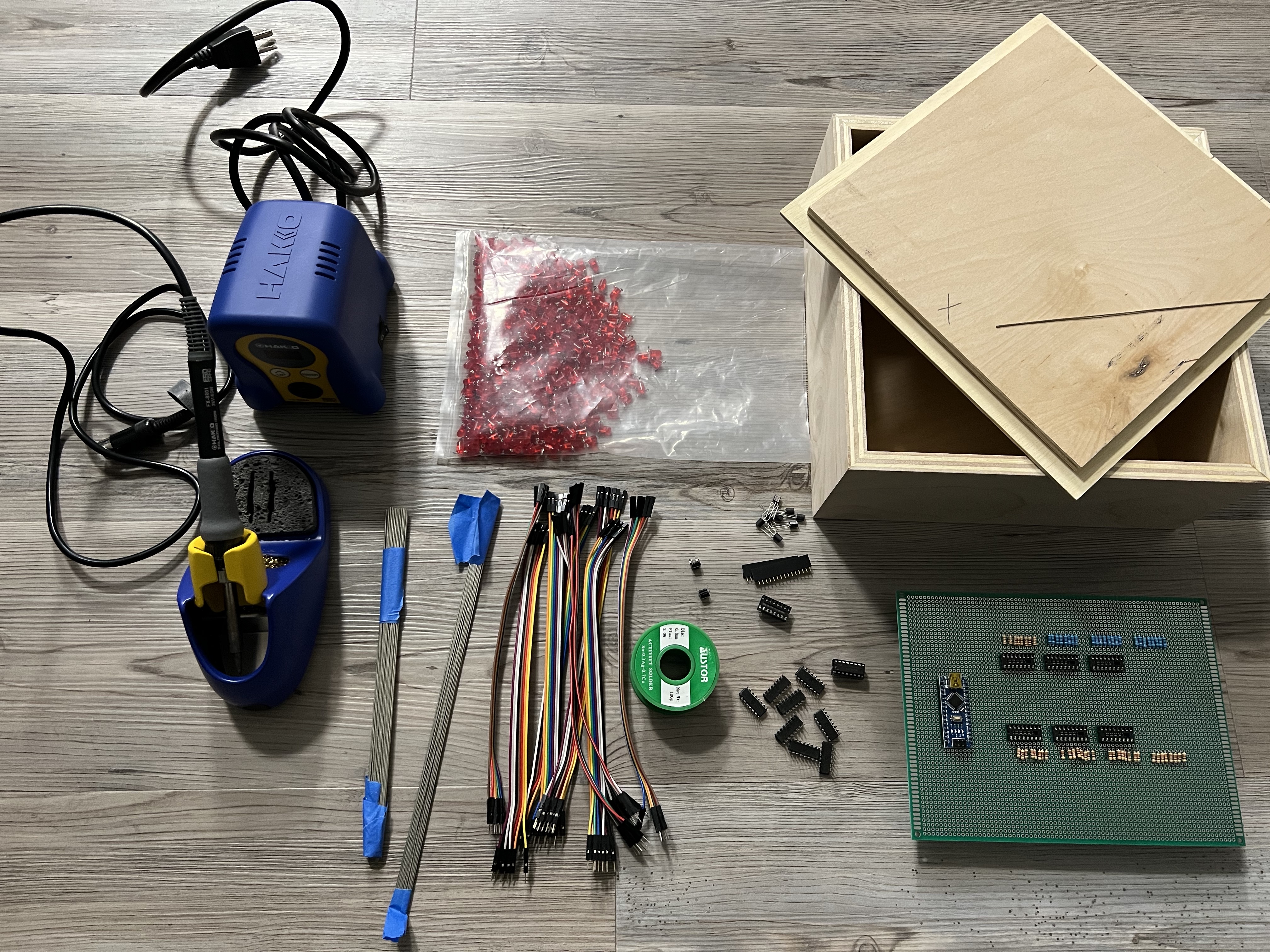

Materials and Enclosure

- Soldering Iron Kit

- 1 arduino uno.

- 512 red LEDs

- 64 150 ohms resistors

- Galvanized wire

- Solder Wire

- 9 shift registers 74hc595

- 1 chip (uln2803)

- 9 ic sockets of 16 pins

- 1 ic socket of 18 pins

- PCB Board

- Jumper cables (approximately 70)

- 1 momentary button

- On and off switch

- 5 volt power outlet

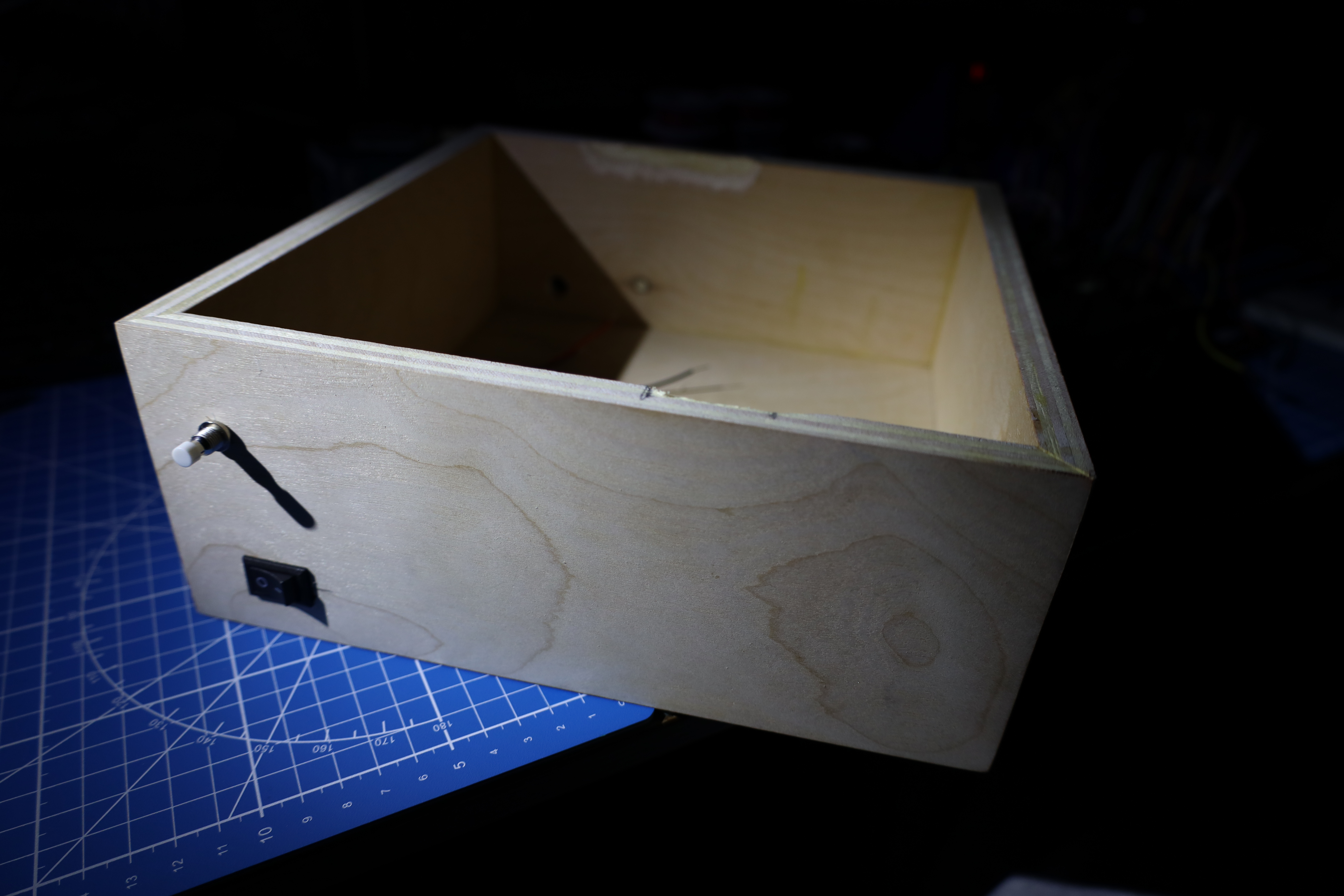

Close up look at the enclosure for all the hardware of this project.

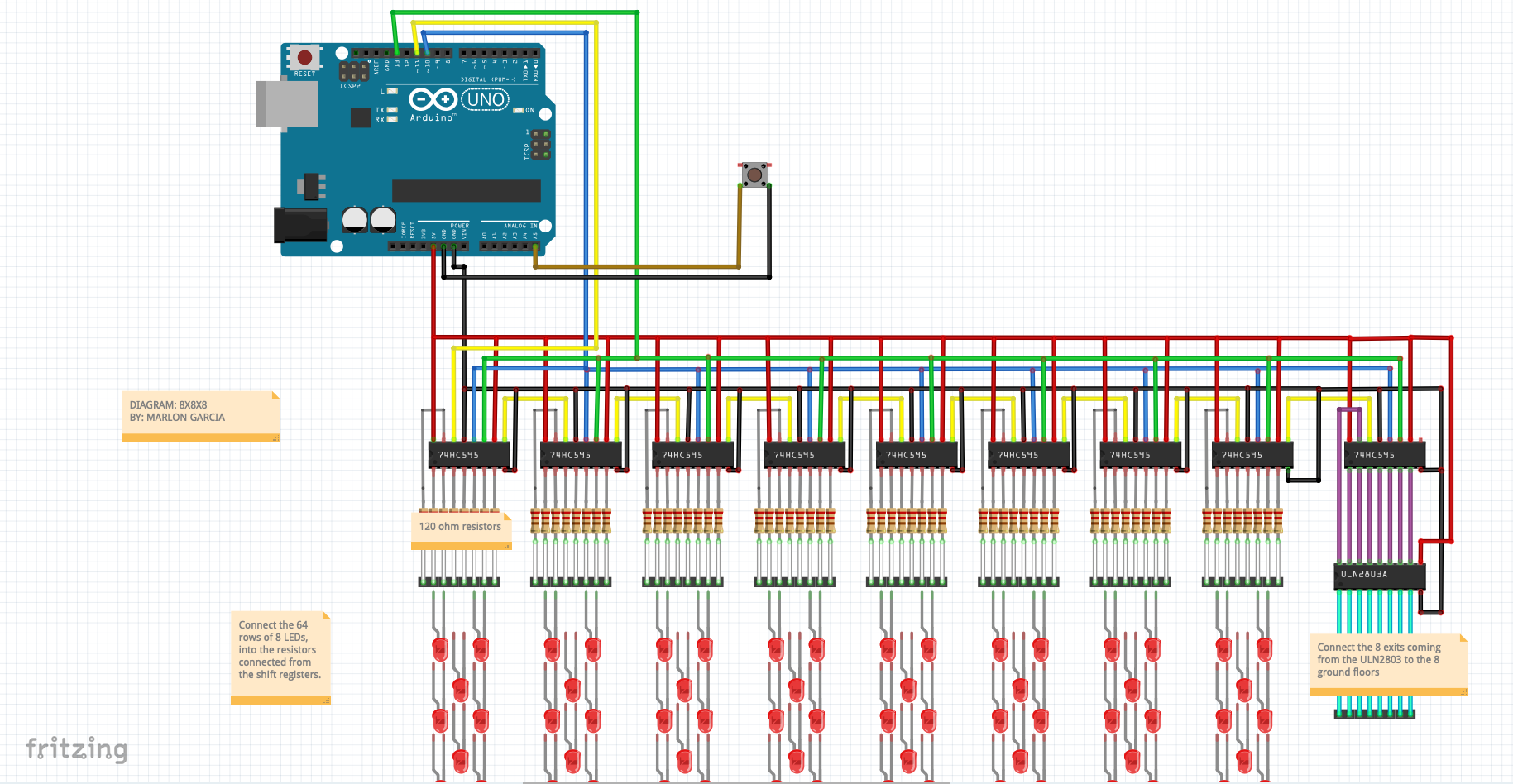

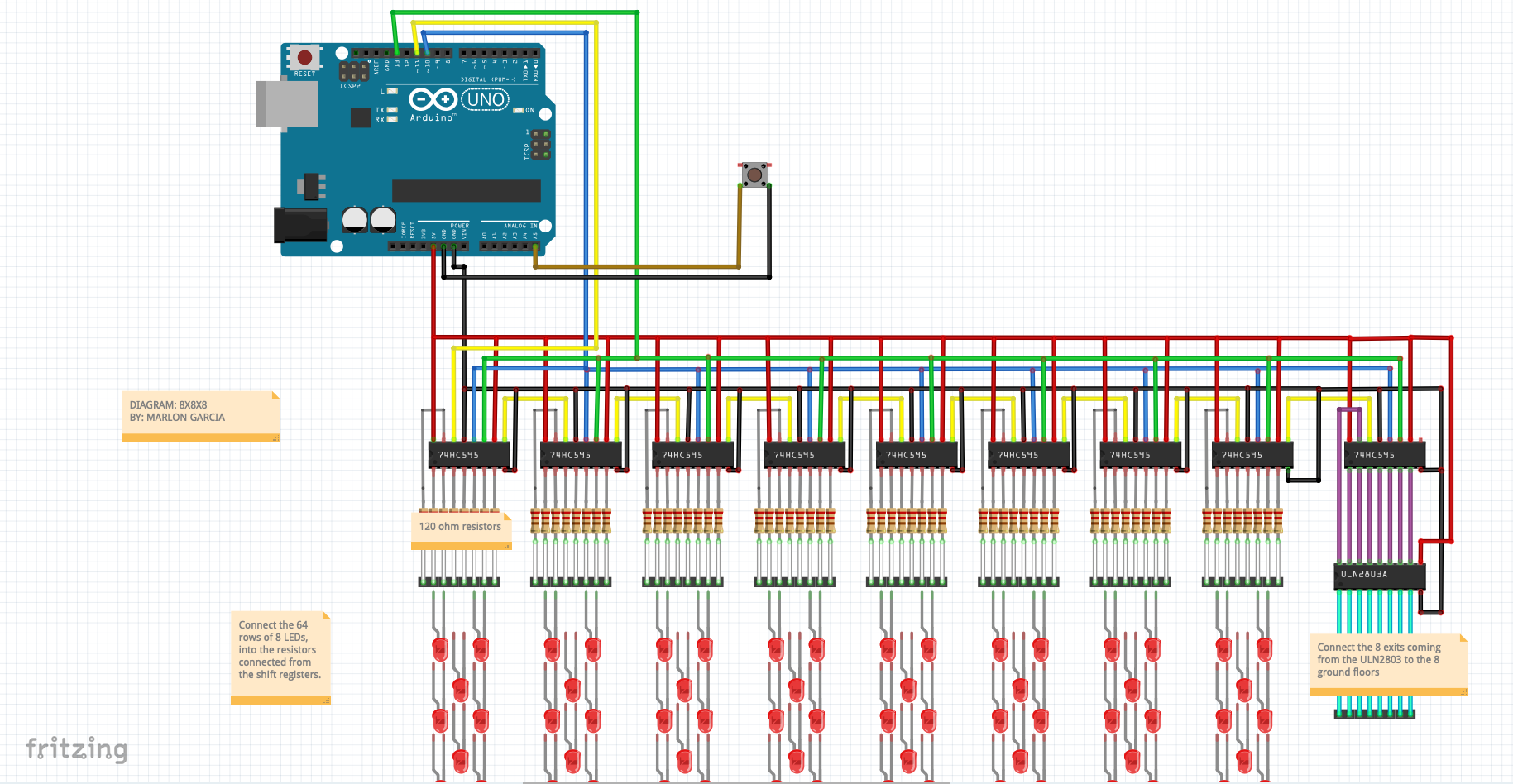

Diagram

This diagram allows me to see where connections need to happen, how

arduino uno connects with either solder wire or jumper wires sending data

from the chip itself to the shift registers and the ground levels to the

LEDs and successfully sending data.

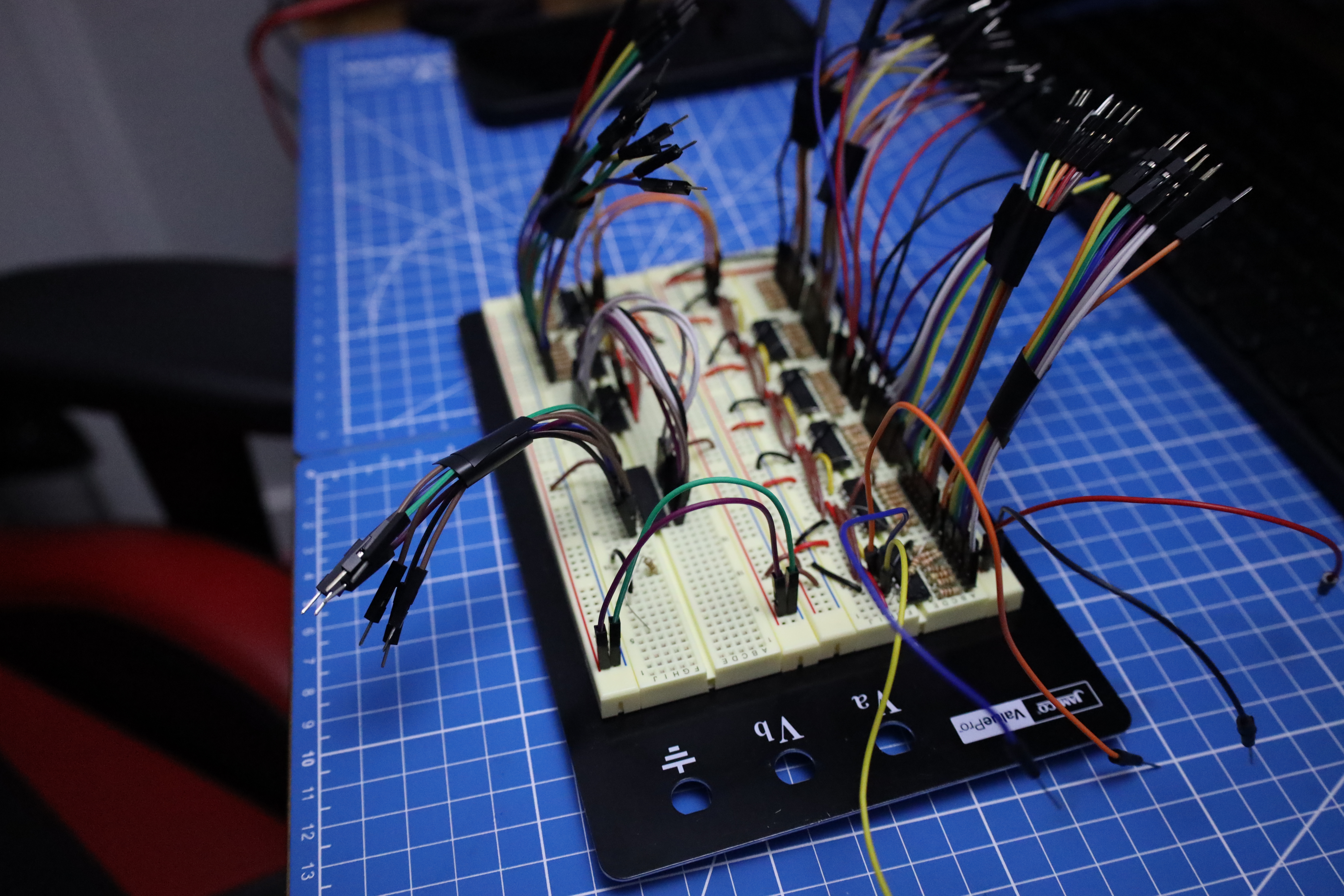

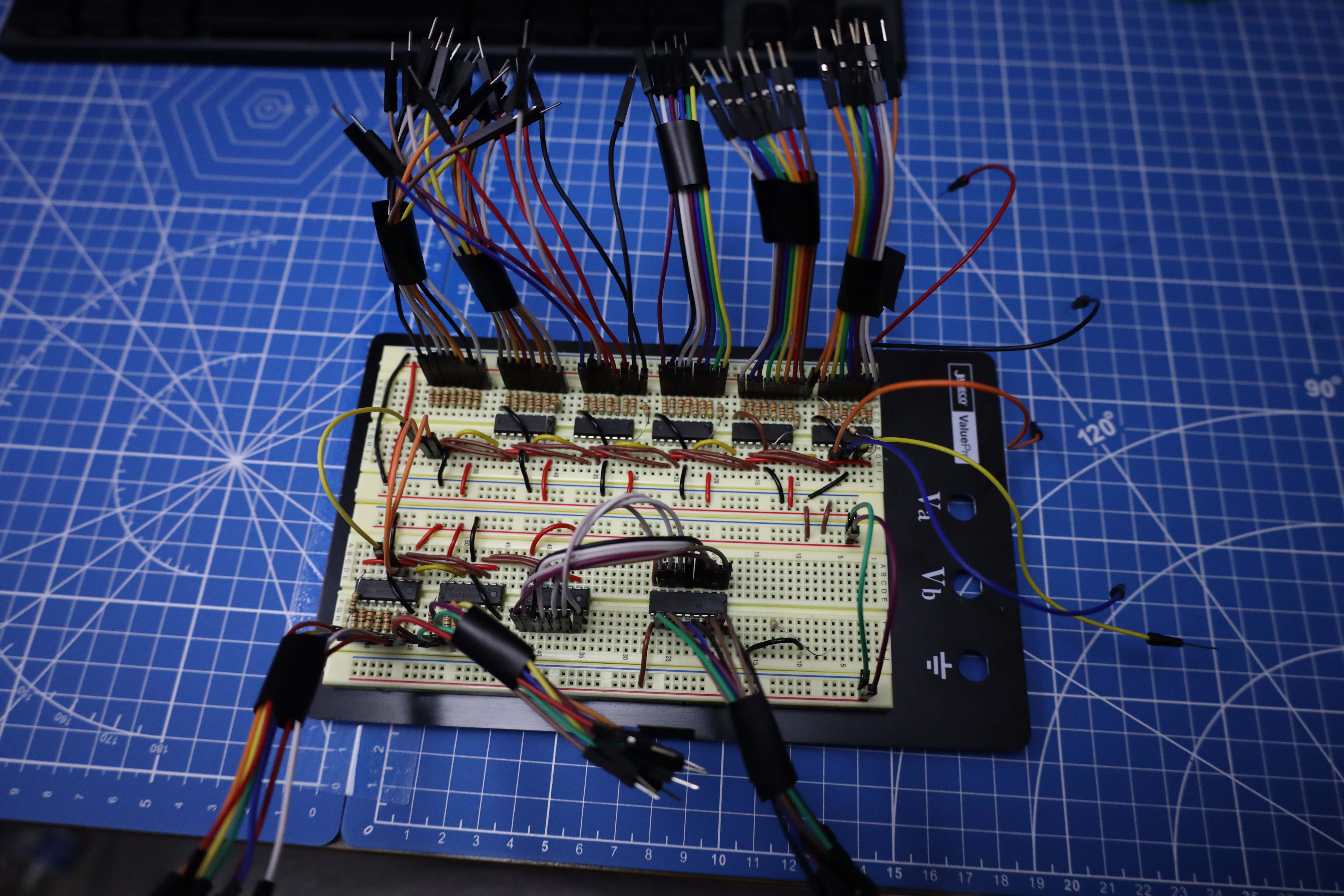

Prototype

In this phase of my project I used a breadboard to make every single

connection following the diagram below and making sure the project was

functionable. In this state I tested LEDs in order to verify that arduino

was sending data and LEDs were functionable.

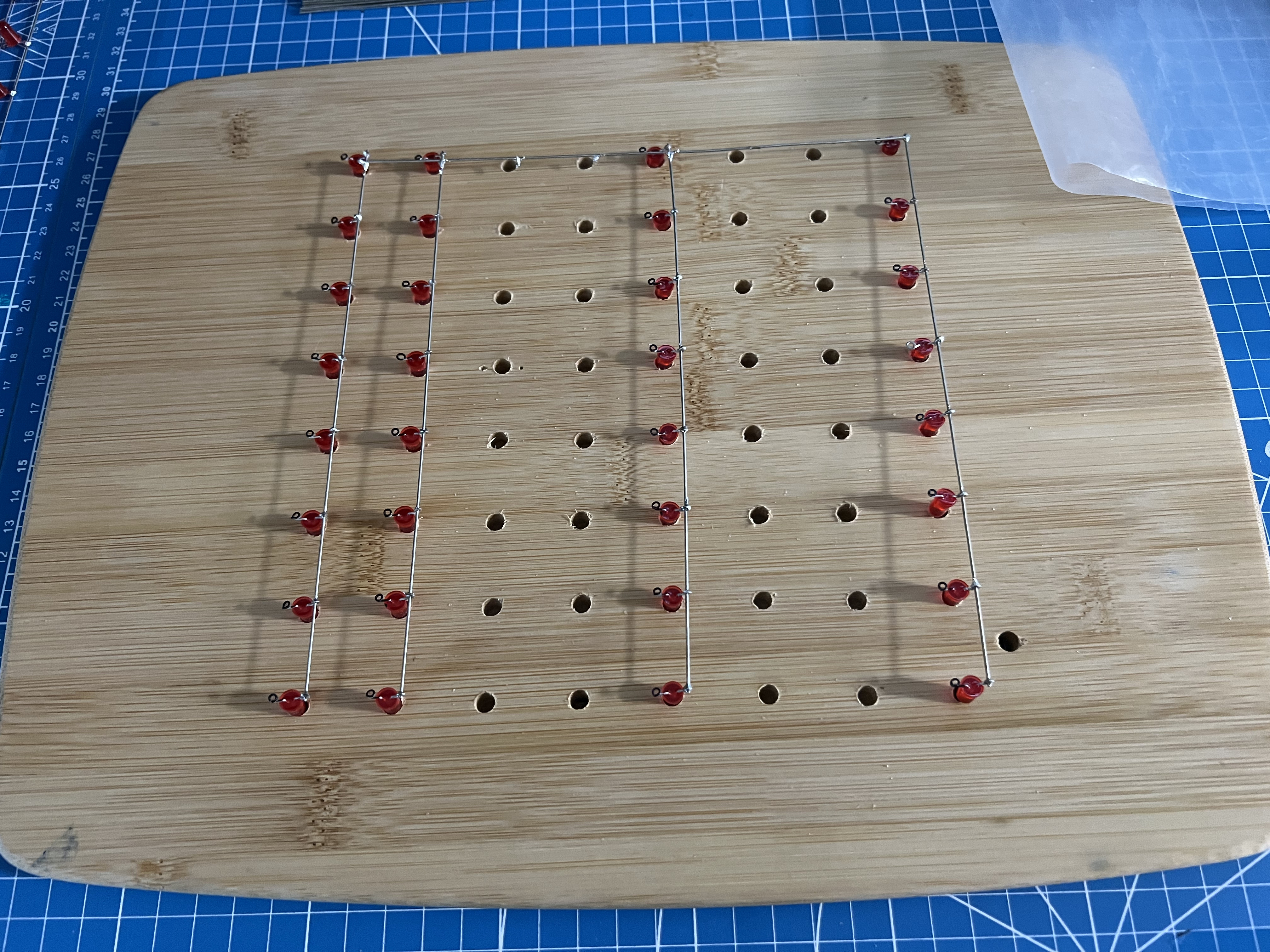

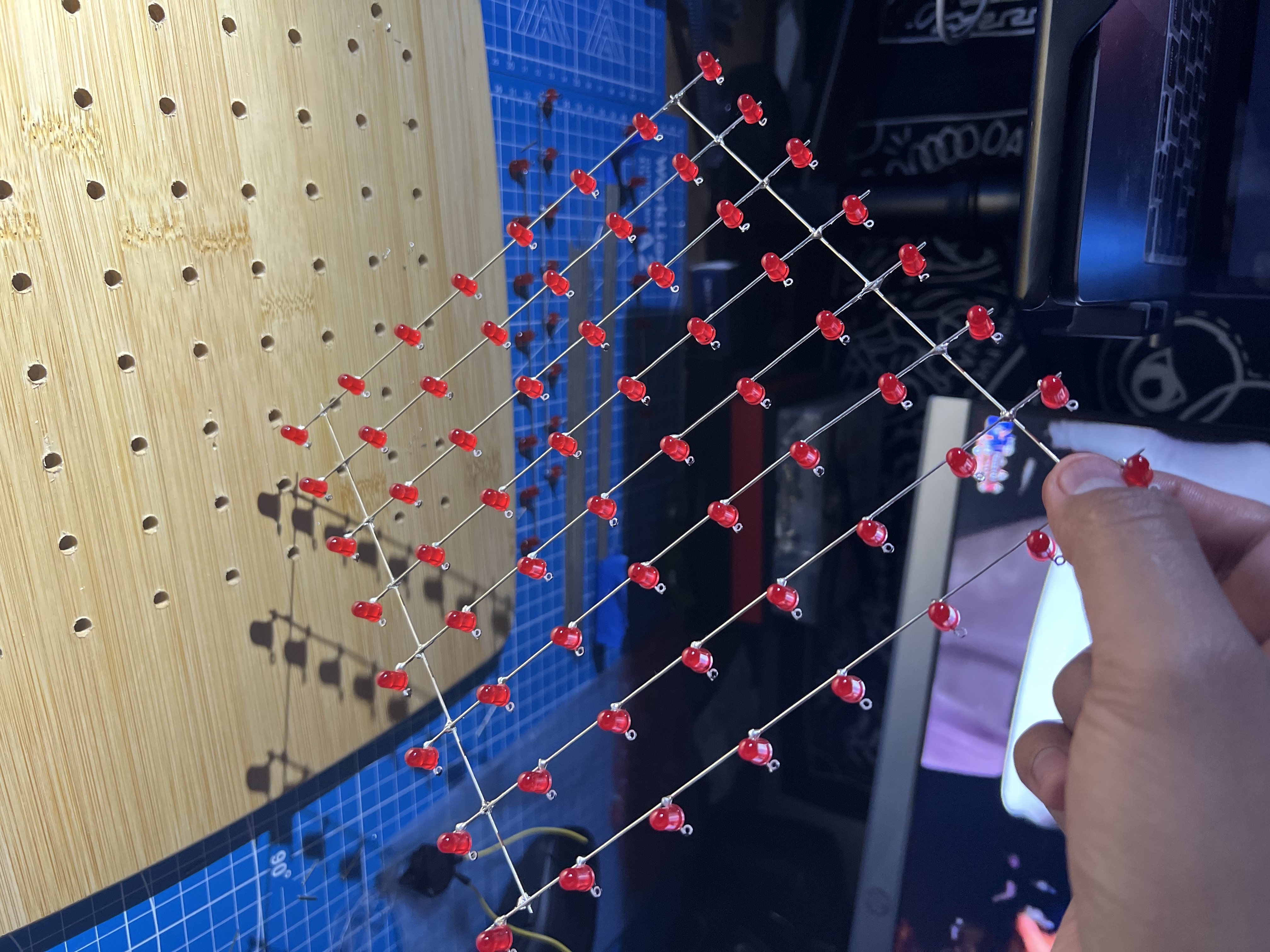

Working Progress

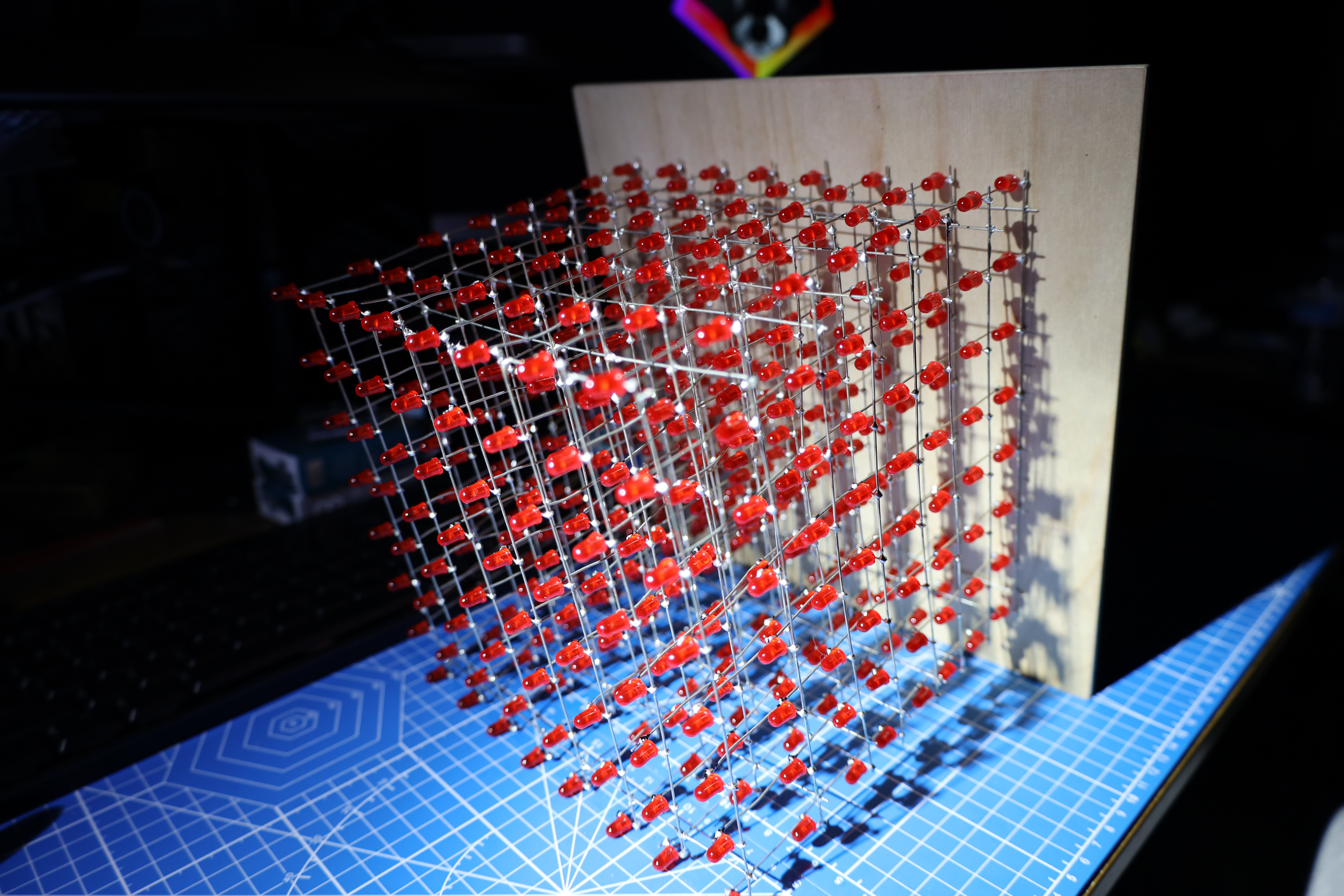

After Figuring out how everything was going to be assemble it was time to

start making the 8x8x8 cube, at this point there was only a matter of

patience and lots of soldering. The way the cube was made was, created a

grid of 8x8 of 1 inch apart from each whole and put every LED in one of

the holes. I also took some time making the negative and positve leg of

each LED round so I could facilitate my work when I was about to start

soldering the LEDs.

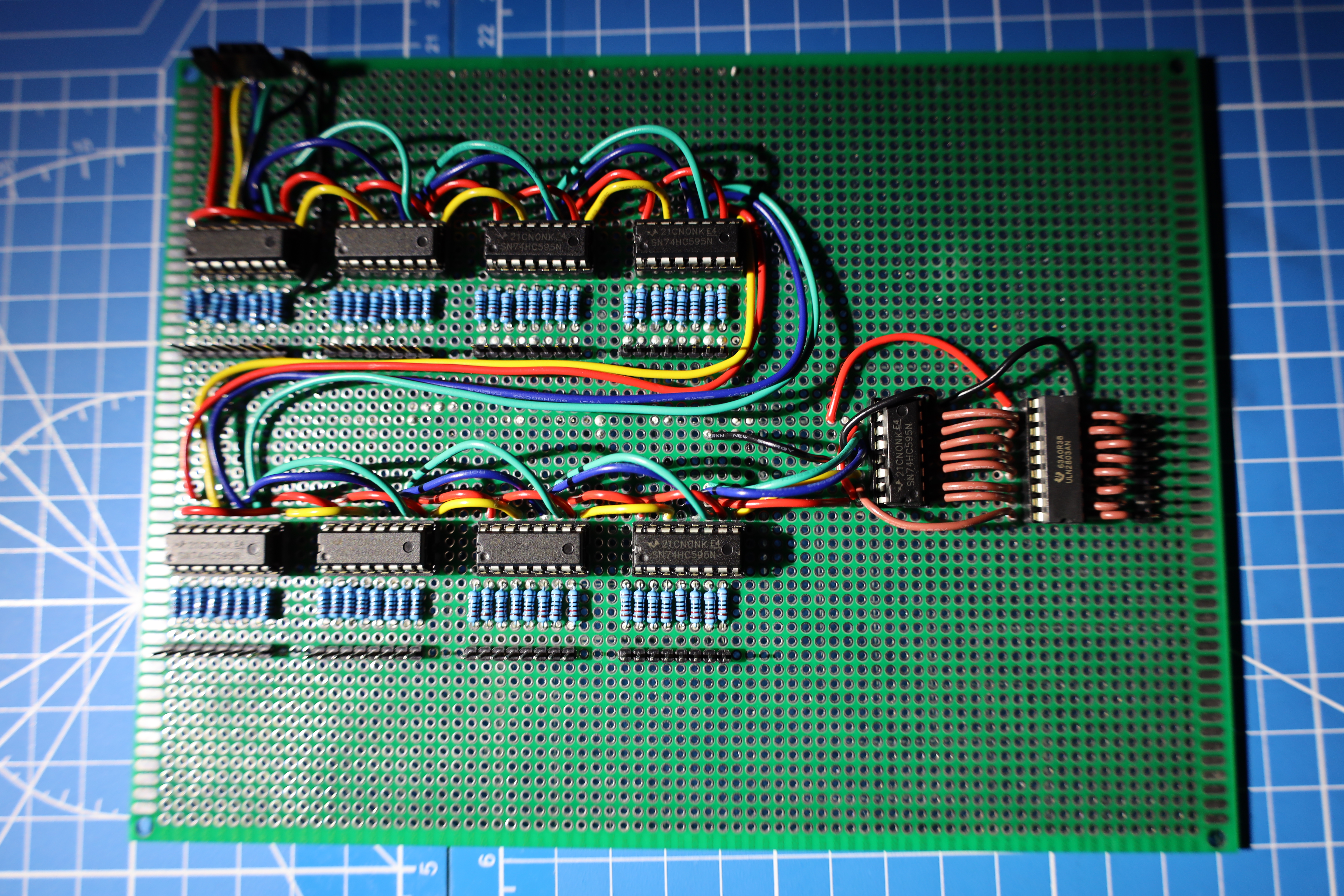

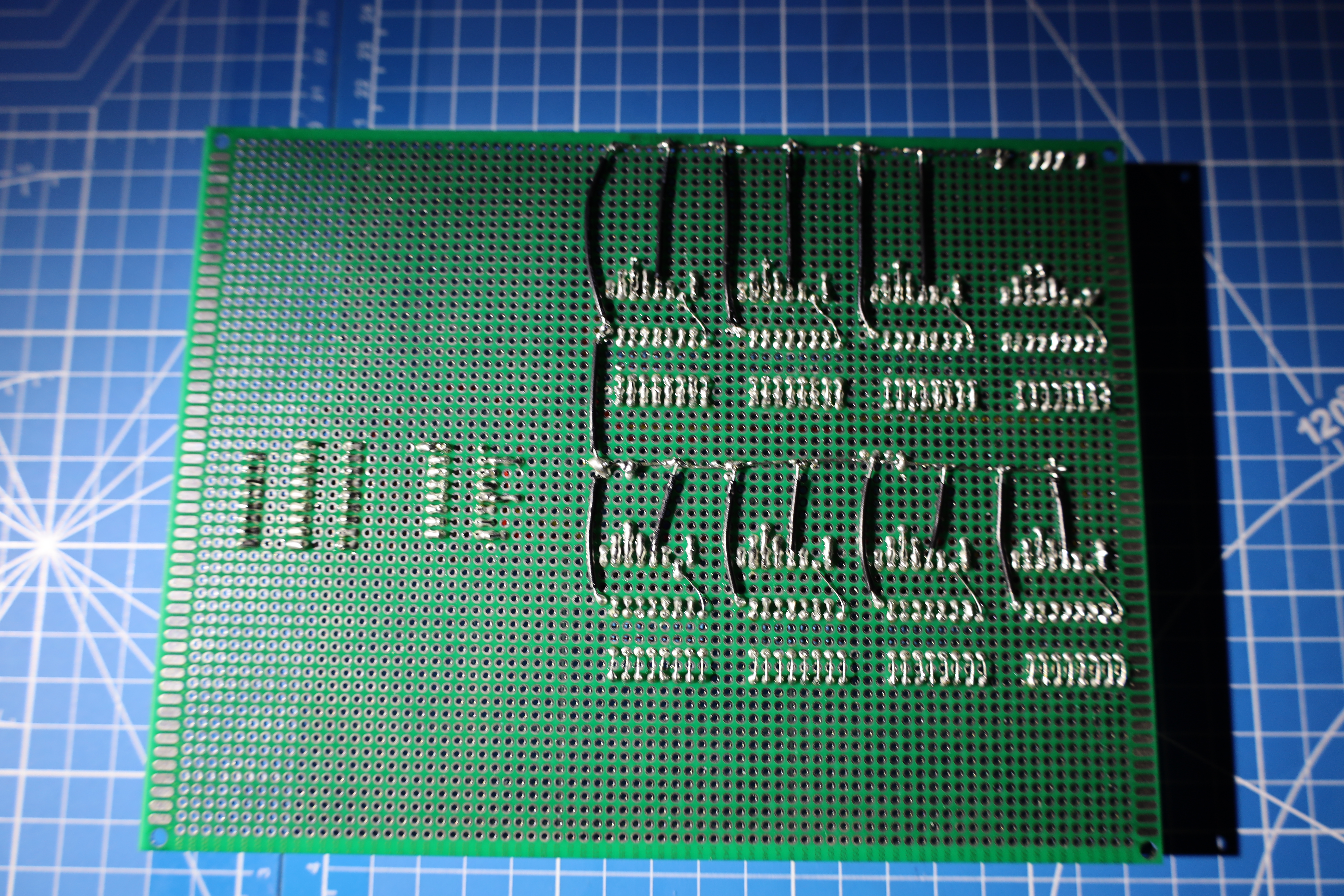

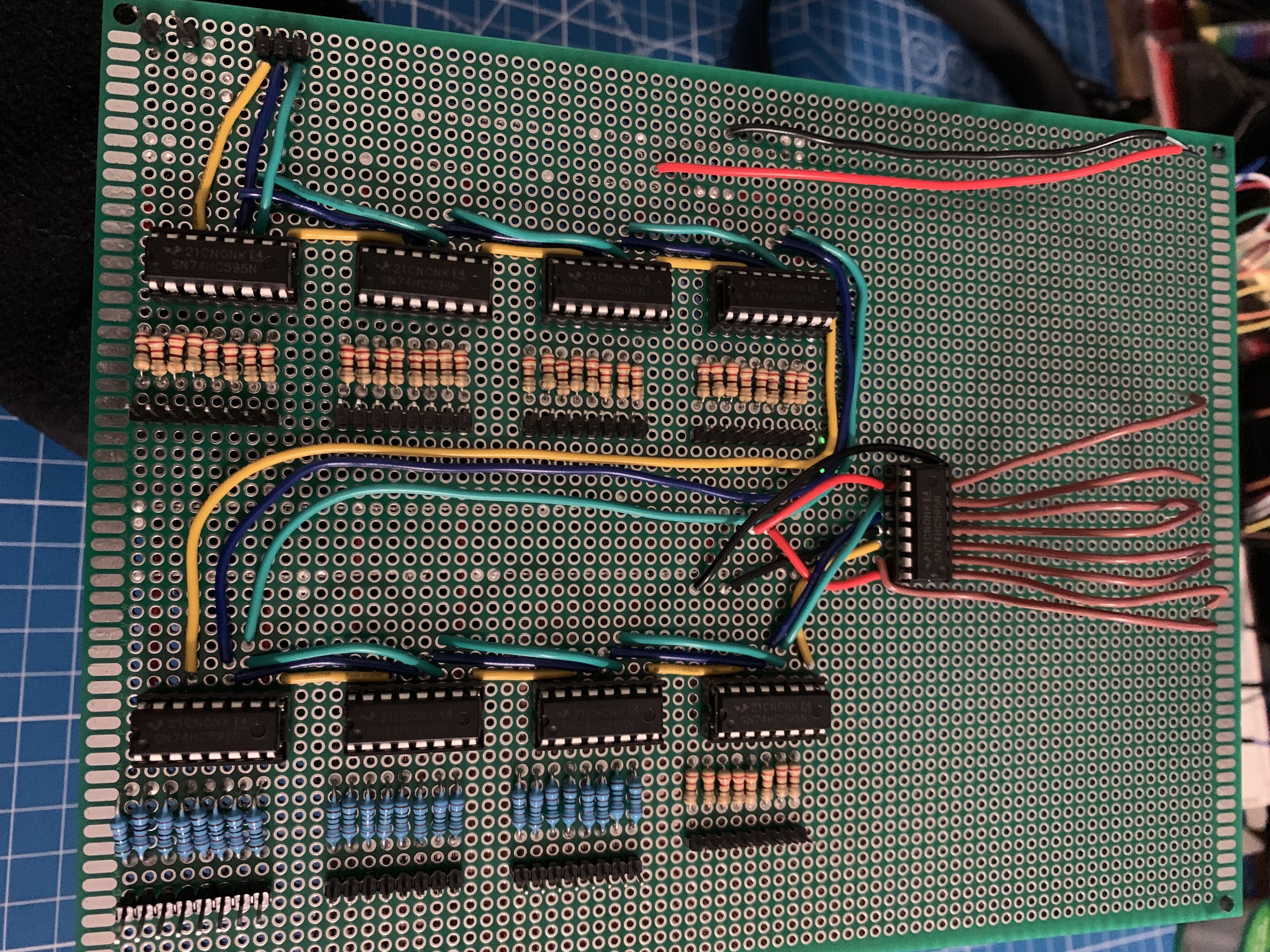

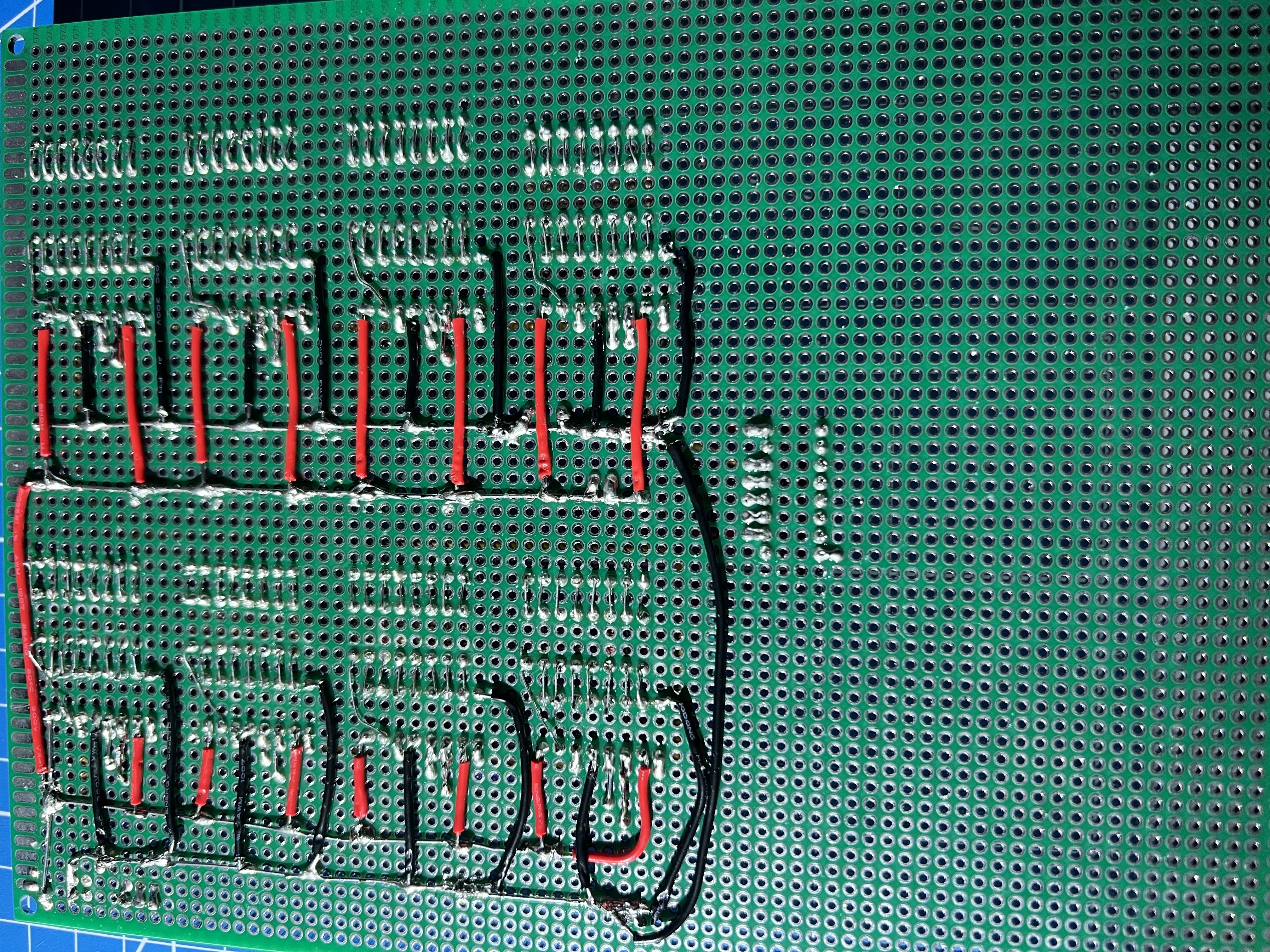

Soldering PCB Board

At this stage of the project, with the help of the diagram, I was able to

solder the PCB board, every connection was verified with a multimeter, no

bridges were created on the conncetions made. There was one line for

ground, one for volts, one for datapin, one for the clockpin and one for

latch pin. There was also connections on every resistor and also

connections to the 8 ground floors and the 64 positive LED rows. IC

sockets of 16 pins were used to mount the shift registers 74hc595 and one

ic socket of 18 pins to connect the uln2803.

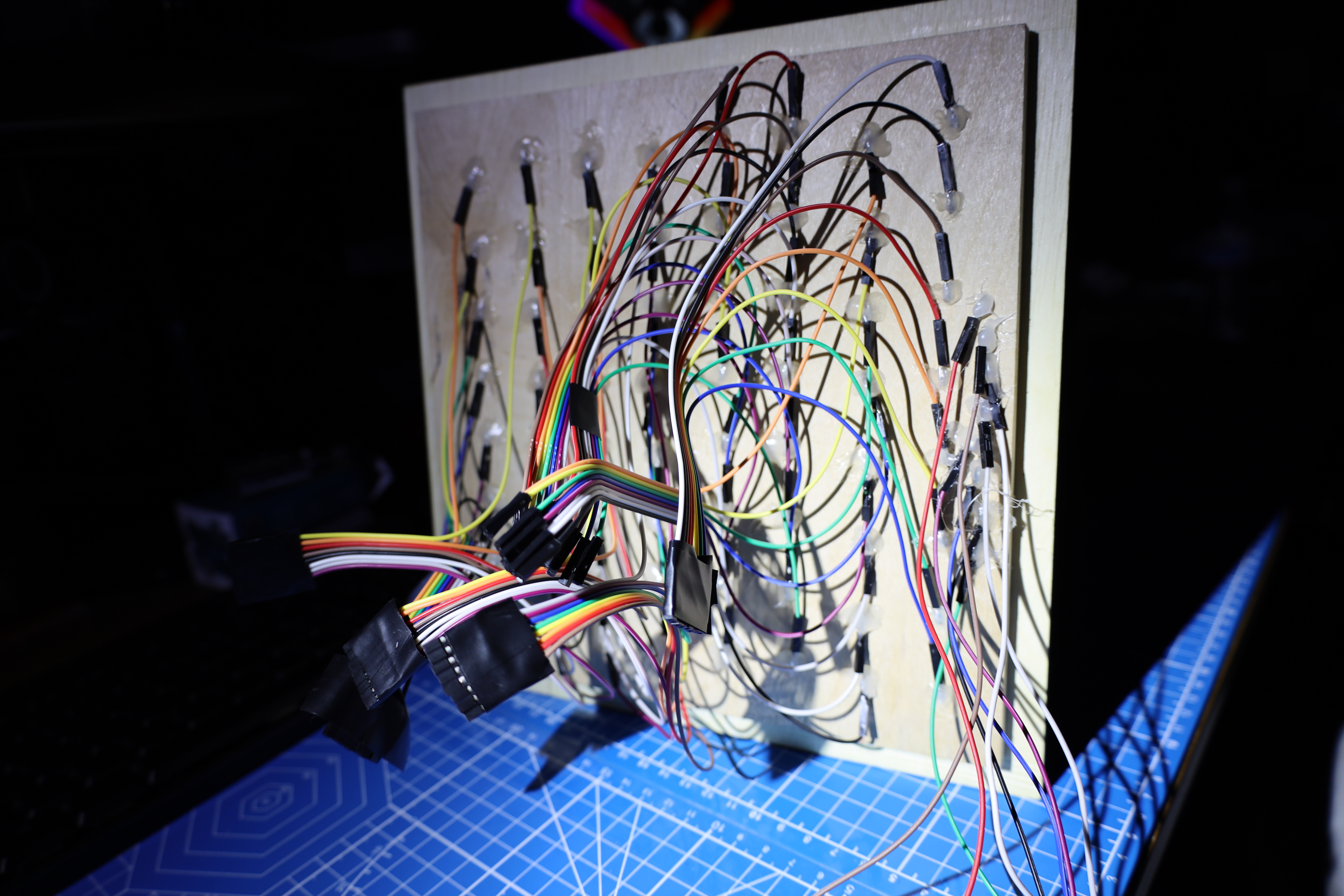

Finished Cube and Connections

After a long soldering process, The cube was finalized and mounted into

the lid of the enclosure, in the second image we can see the connections

to every single positive exit of the 64 rows of 8 LEDs coming from the

top. Everything was kept as clean as possible and organized so it wouldn't

create any confusion when connecting every cable into the finished PCB

Board.

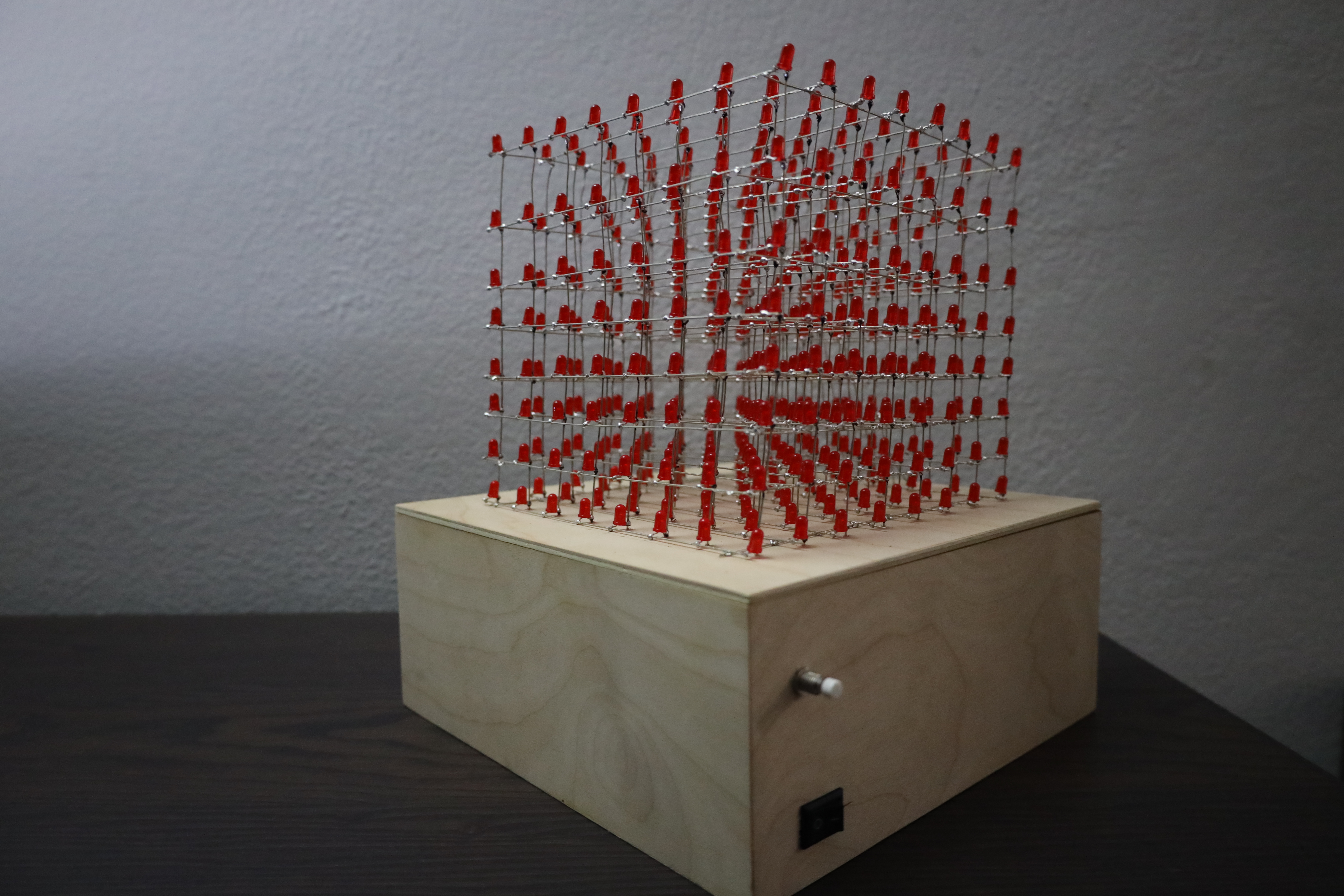

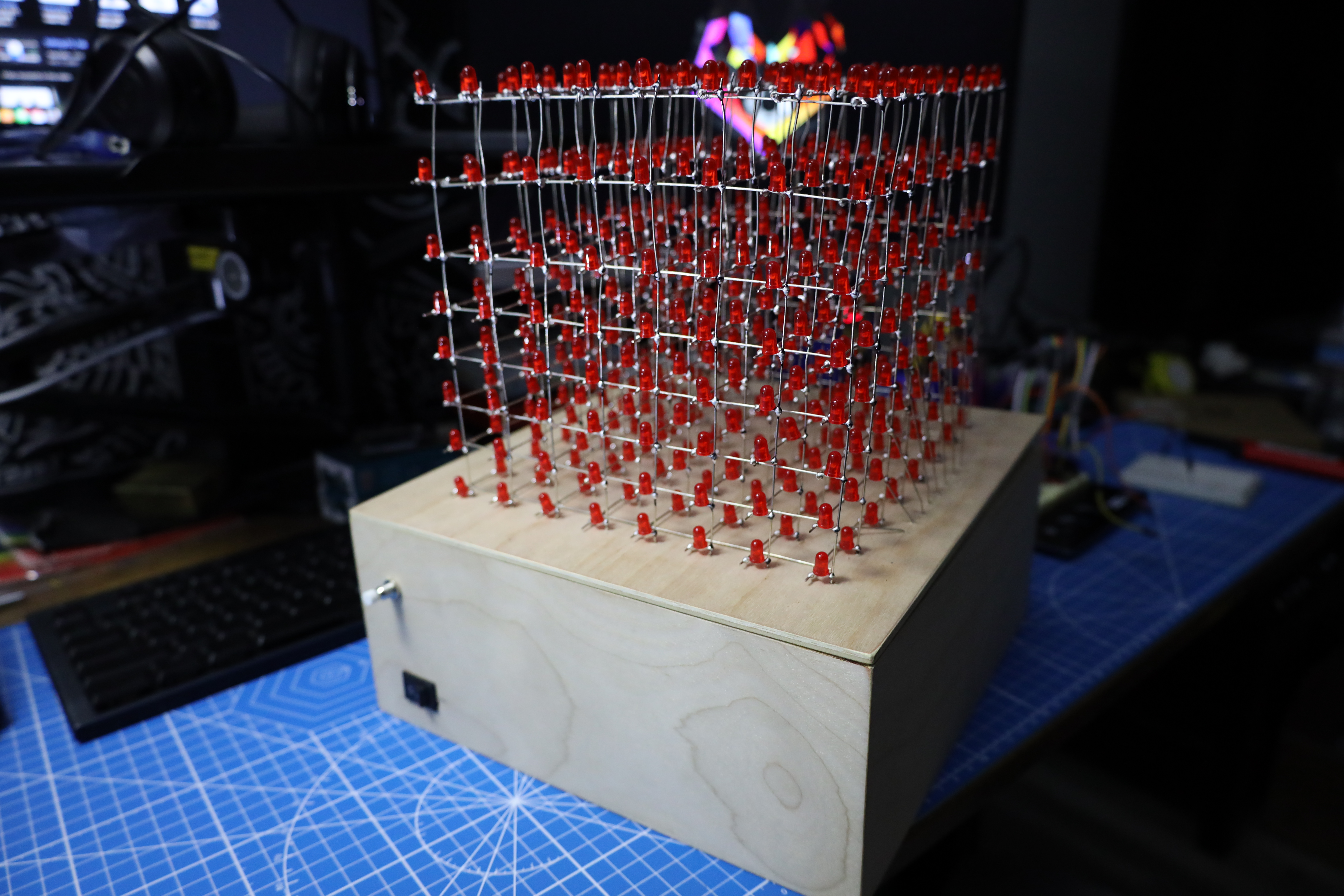

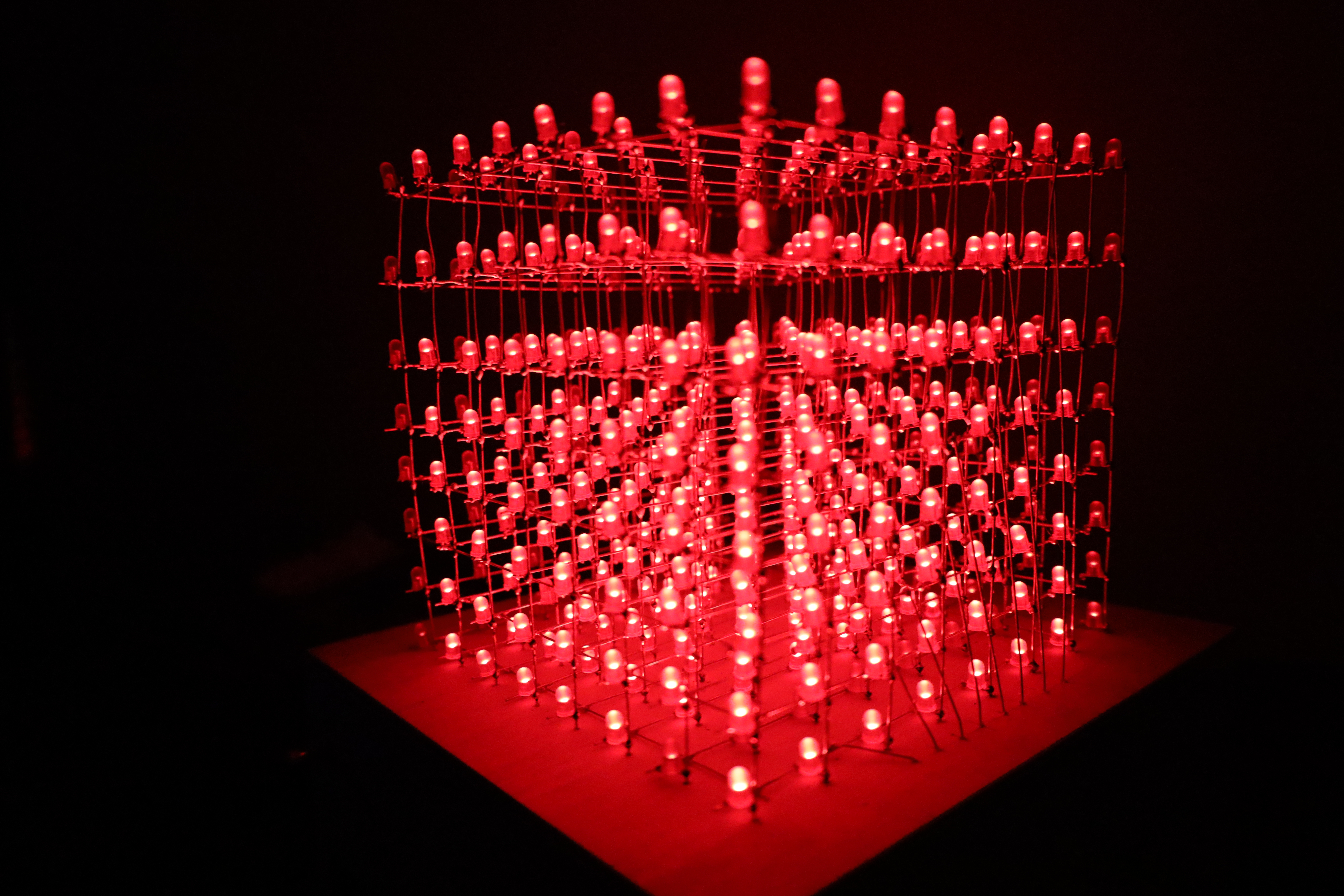

Finalized Project

In the final phase of my project, we can finally see the finished piece,

on the left image we can see the cube turned off but with the right amount

of lighting that displays every single detail of the cube and box. On the

second image to the right, we can see the cube and the enclosure in a

different angle.

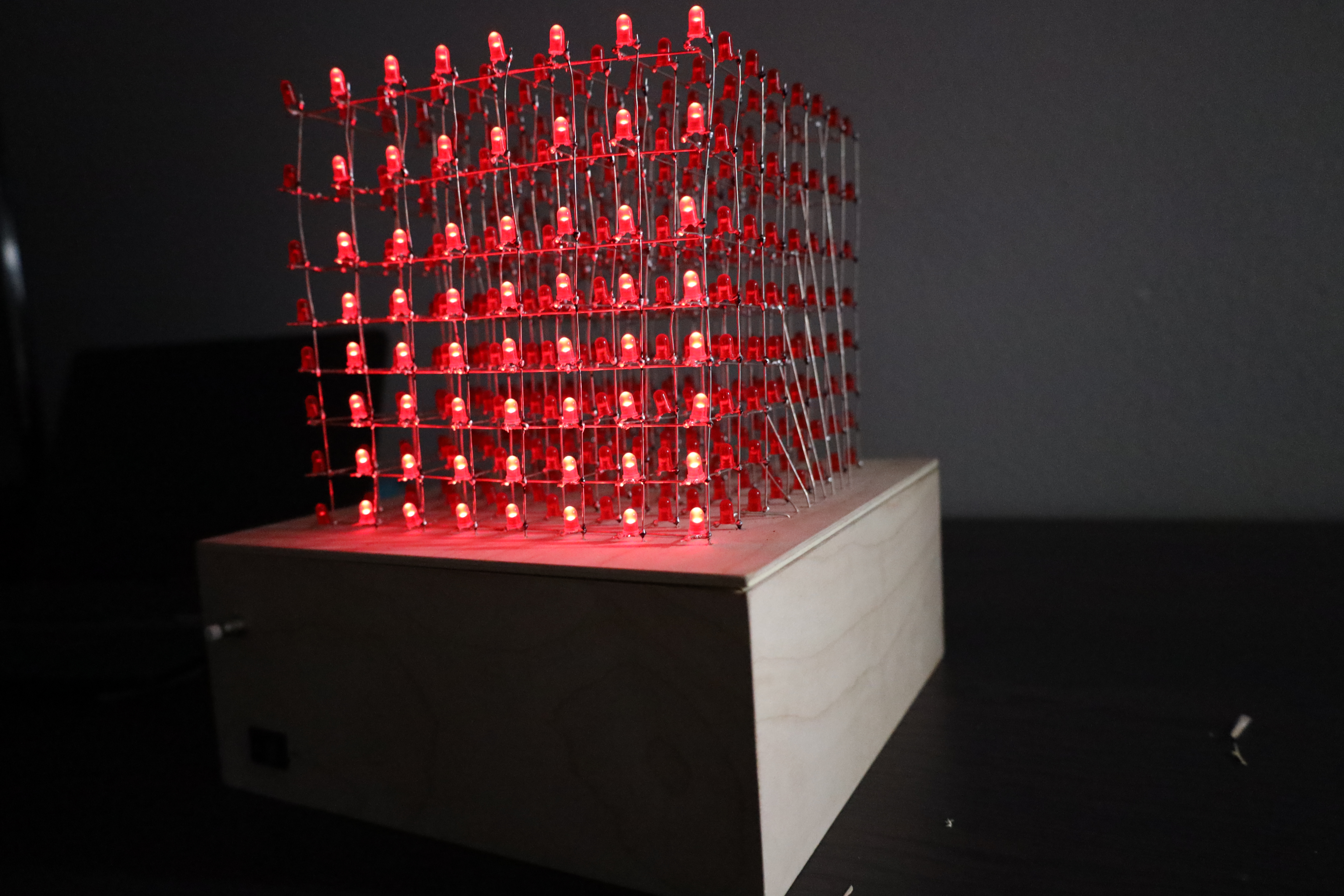

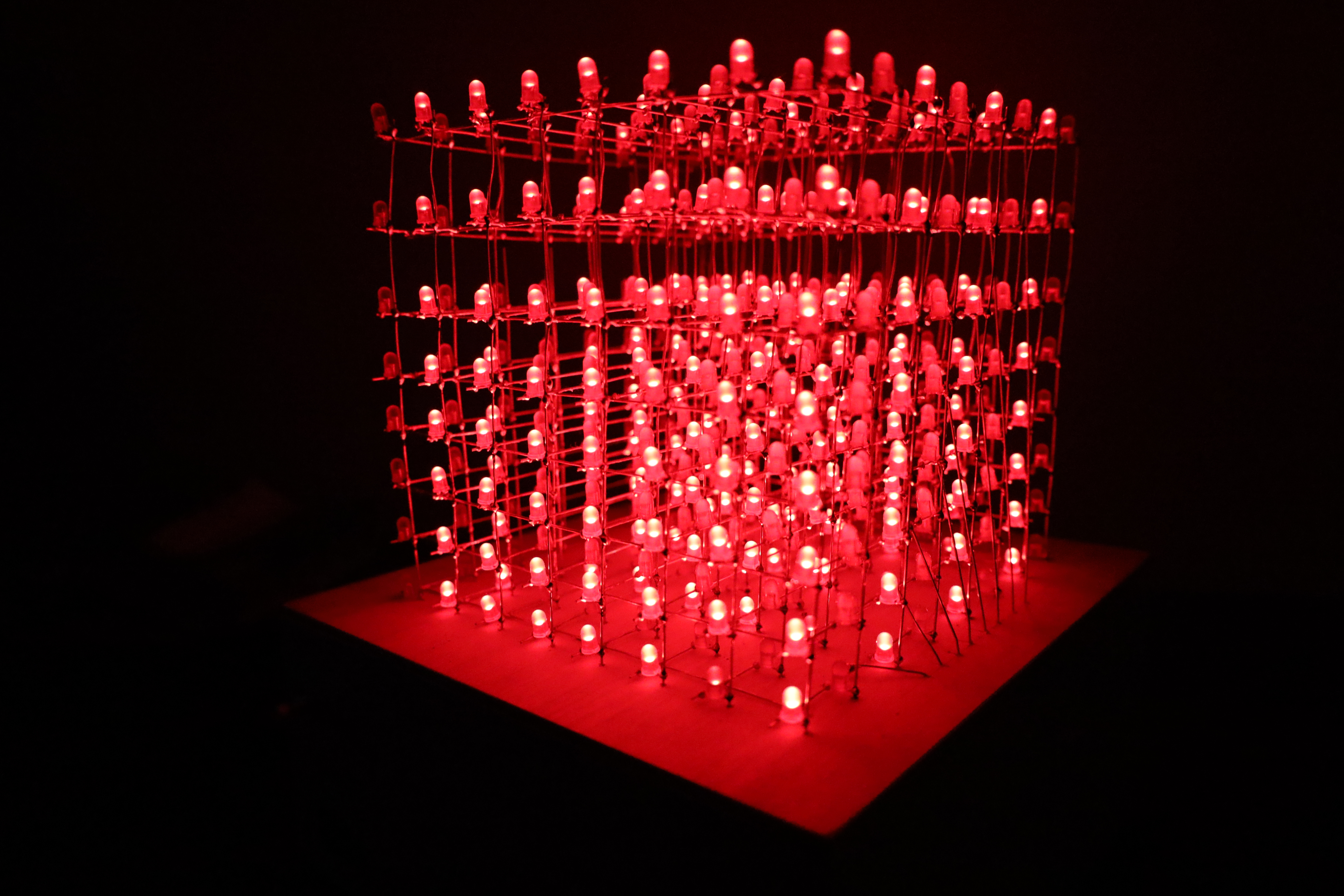

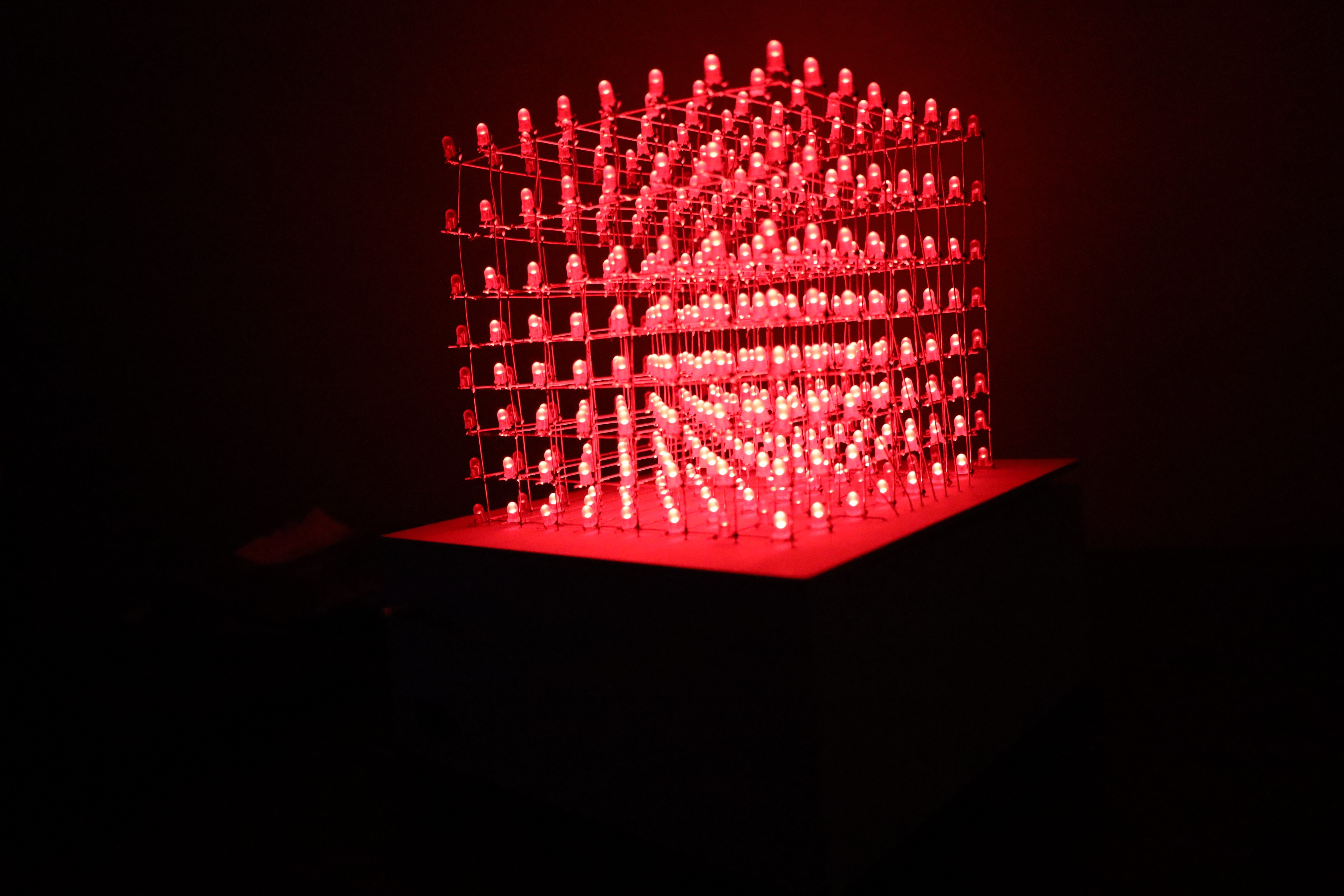

Finalized Project 2

In the end of this project we see four differnent images that display

different designs on the lighting. Different angles and different lighting

to see the difference in space and lighting that the LEDs create.

Final Project Video

After roughly 50+ hours of work, I can happily say I achieved what I was

looking for when thinking what I wanted to make for my graduation project.

I overcame many obstacles, shear some tears when things were not going the

right way, rebooting, resoldering, and tons of dedication in order to

achieve my goal. I am happy to say that my stay at SJSU has given me the

ability to create things I never thought I could. This project also

represents what I initially wanted my project to represent. Nolstalgia

played a huge role not only here but in most of the pieces I creat myself.

I am a true believer that practice makes perfection and this project is a

clear example of it.

---Issues I found while making this project---

While making my first soldering PCB Board, I never checked any connections

with a multimeter and that was my biggest mistake in this project, I

created bridges from the ground connections to the 5 volt connection and

every time I tried connecting the cube it was overheating and at some

point, the power outlet was smoking. I lost roughly 5-10 hours of

soldering work with this mistake. Using a multimeter will save you time,

mistakes and frustation.